KITE HOVER MOTOR

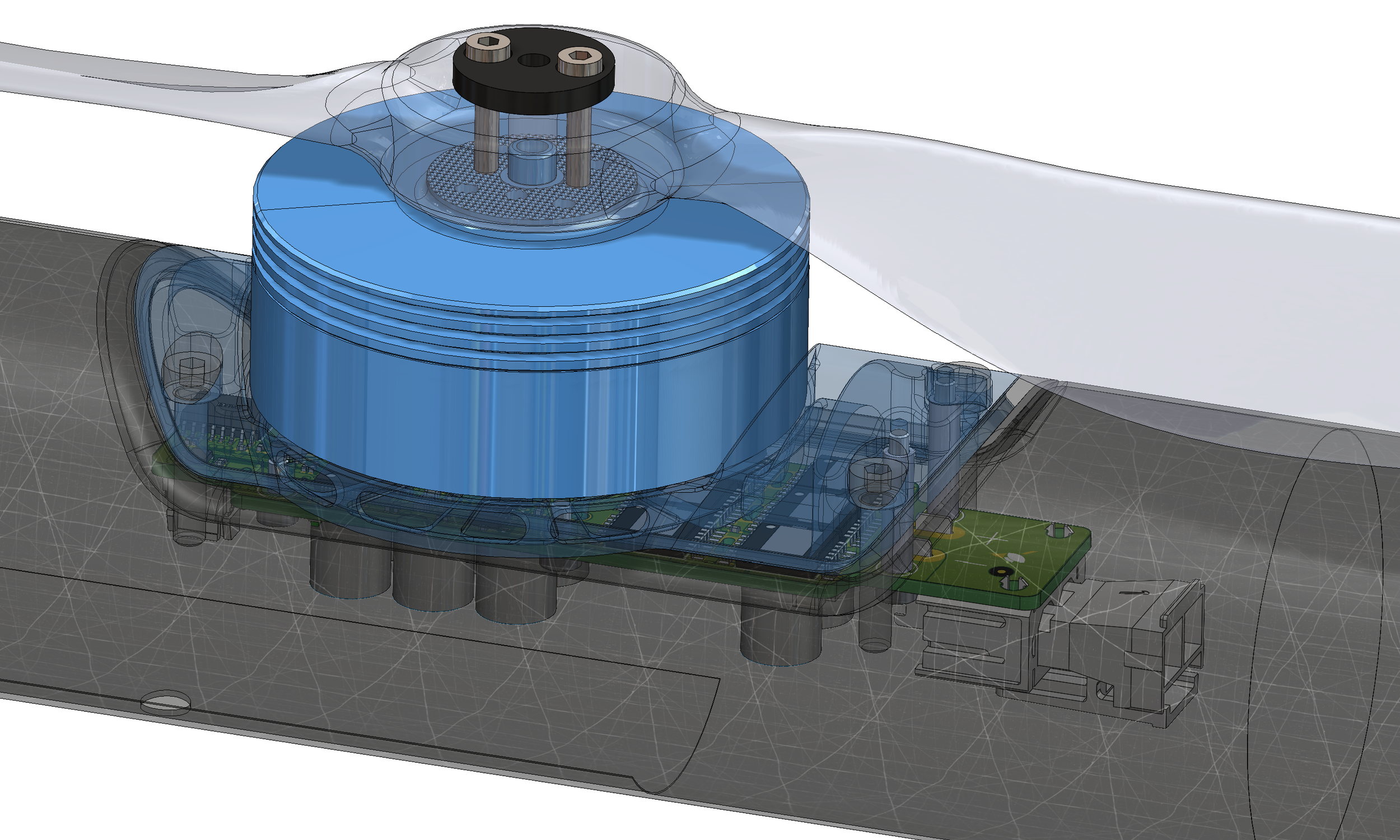

The motor controller uses the motor base as a heat sink. Then optimized cooling paths within the motor cool the motor module during flight

3

The mosfets on the hover motor speed controller board generate significant heat while aircraft is taking off and landing. The speed controller board utlizes the thermal mass of the hover motor and the convective cooling through the motor stator to increase motor efficiency and reduce weight.

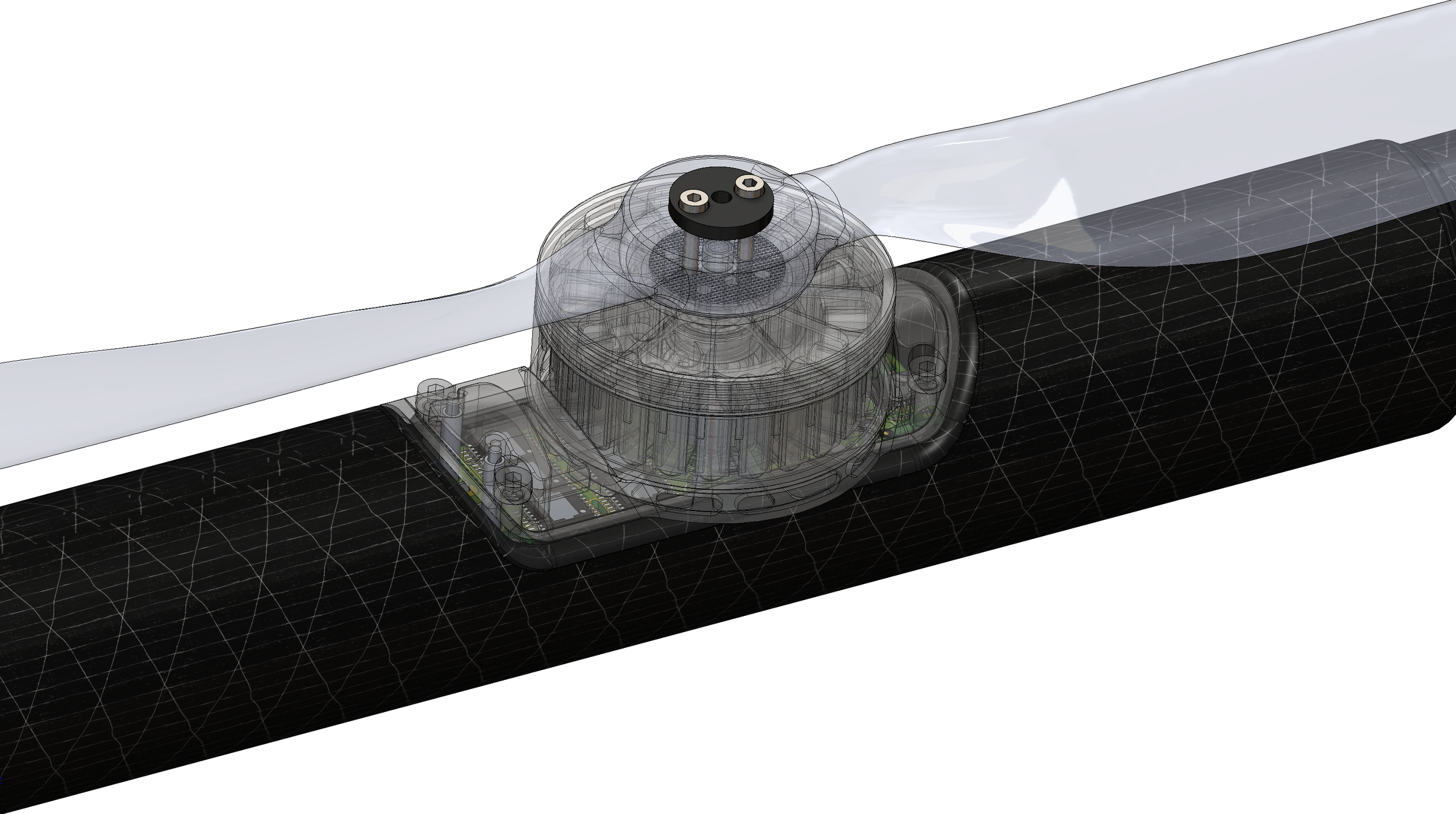

Seamless Integration

With just 4 screws and 2 electrical connectors, a Hover Motor Module can be replaced in under 10 minutes.

Revolutionary Design

Digital Parachute -

4 hover motor pairs gives Kite full redundancy. Kite can fly safely in the event of a motor failure.

Innovative Thermal Management -

Motor controller uses convection-cooled motor base as a heat sink.

Seamless Integration -

The hover motor base has been machined to the profile of the motor booms while being lighter than the original motor base. Additionally, the Hover Motor attaches to aircraft with just two electrical connectors and 4 bolts.

1

Digital Parachute

2

The Kite Hover motors are fully redundant. Up to 4 can fail during flight, and the aircraft can still complete the mission. Redundancy architecture currently pending approval by the FAA.